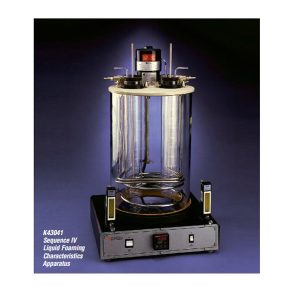

Foaming Characteristics Lubricant Oils

Foaming Characteristics Lubricant Oils

Compliance standards

- ASTM D892, IP 146, ISO 6247

Construction Details

- The complete assembly consists of following parts and accessories.

- 1. Foaming Bath Apparatus - (Glass jar with TWO Test Cylinders and combined Heating & Cooling arrangement)